At FRIMA Machining, we specialize in CNC turning services to mass-produce parts or product prototypes. We have a lot of experience with general threading and CNC machining of round parts, including shafts, worms and balls. Whether you need one prototype or thousands, we can help you out.

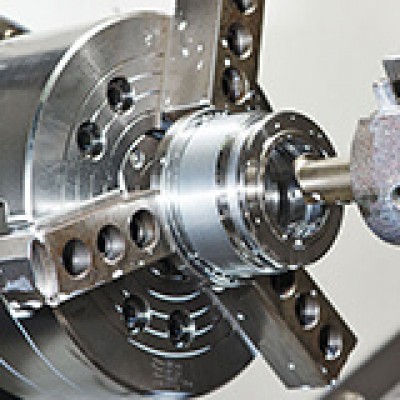

CNC turning is a precise, high-speed machining process that uses a computer-controlled lathe to remove material from a workpiece. This process is typically used to create cylindrical parts with a consistent diameter and smooth surface finish. CNC turning can also create complex external and internal geometries, including various threads. For round parts like shafts, worms, spheres. However, for other angular parts, CNC milling may be more effective.

Advantages of CNC turning

CNC turning is especially well-suited for creating small, precise parts that would be difficult or impossible to make using other methods. This makes it an ideal choice for applications in the medical, aerospace, and electronics industries. In addition, CNC turning can be used to create complex parts with multiple features, such as thrCNC (computer numerical controlled) turning is a widely used machining process that offers several advantages over traditional turning methods.

CNC turning is more precise and can produce more intricate designs than traditional methods. It is also faster and more versatile, making it ideal for a wide range of applications. The main advantages of CNC turning are:

- CNC turning machines are very efficient at creating round or cylindrical parts.

- You can carry out a variety of different cuts on CNC turned parts, including drilling, boring, threading, and knurling.

- Parts produced with CNC turning are usually of a very high quality.

CNC turning metals and CNC turning plastics

There are a few things to keep in mind when choosing a CNC turning process for your project. First, you need to decide what type of material you want to use. Metals, such as aluminum and steel, can be machined using CNC turning, but plastics such as acrylic and polycarbonate can also be used. Second, you need to decide what size and shape you want your finished product to be. CNC turning can create parts with very tight tolerances, so you can be sure that your product will be the exact size and shape you need.