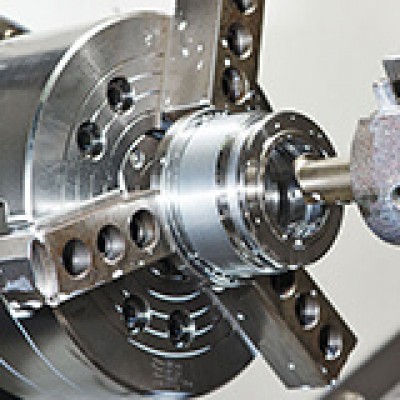

Top Quality CNC Swiss Machined Parts

At FRIMA, we pride ourselves on providing the highest quality CNC Swiss machined parts in the industry. We use the latest technology and the finest materials to produce parts that meet the strictest standards. Our parts are used in a wide variety of applications, from medical devices to aerospace components.

Benefits of CNC Swiss Machining

CNC Swiss machining offers many benefits over traditional machining methods. Swiss machines are able to produce parts with complex geometries and tight tolerances. Additionally, CNC Swiss machines can operate at high speeds, which makes them ideal for mass production. Swiss machines are also very versatile, able to produce parts from a variety of materials including metals, plastics, and composites.

FRIMA is one of the many manufacturers around the world who are using Swiss machining methods to obtain extremely small custom machined parts at breakneck speed and with high precision. The reason is that Swiss CNC machining offers a wide range of benefits to manufacturers and their customers. The outstanding advantages of Swiss machining include:

FRIMA is equipped with some of the latest and most advanced CNC Swiss machining equipment available on the market. This allows us to offer our customers Swiss machined components with shorter lead times and reduced cycle times.

What meterial are usually used in Swiss CNC machining?

Swiss CNC machining is a subtractive manufacturing technology. The process is typically used for small, complex parts with tight tolerances. Swiss CNC machines are able to produce parts from a variety of materials, including metals, plastics, and composites. Common metals used in Swiss CNC machining include aluminum, brass, and stainless steel. Plastics such as ABS, PE, and PP can also be machined, as well as composites such as fiberglass and carbon fiber.

| Part |

Application |

Industry |

Material |

Specific Feature |

| Battery Core |

Safety Equipment |

Aerospace |

6061-T6 Aluminum |

Black Anodized Sleeve |

| Alignment Screw |

CT Scanner |

Medical-Health |

718 Inconel |

Burr Free Part for Clean Room Use |

| Drive Rod |

Ink Jet Piston |

Industrial Printing |

AISI 316 Stainless Steel |

Burr Free Rod with 0.0005″ Straightness |

Show All

Why Choose FRIMA CNC Swiss Machining Services?

Our Custom CNC Swiss turning and machining parts are perfect for high volume production runs of small parts. Our high speed and reliability ensures a quick turnaround, improved productivity and shortened production cycle.

Precision Swiss CNC machining can handle your complex parts projects with tight tolerance and high accuracy. And our reduced secondary processing due to the application of live tooling and sub-spindles accelerates the whole process.

Finally, our premium quality and high-grade materials, careful operation, and strict inspection throughout the whole machining process, as well as quality tests for the product ensure that you’ll be satisfied with your purchase.