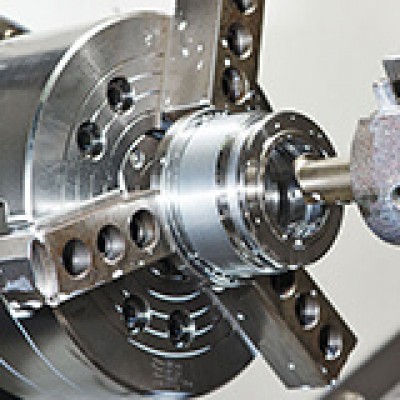

A CNC mill & turn service is a computer-controlled machining process that can create a wide variety of parts and products. The mill & turn process is a combination of two manufacturing processes: milling and turning.

Milling is a machining process that uses rotating cutting tools to remove material from a workpiece. This can be done in a variety of ways, including perpendicular to the workpiece, at an angle, or following a contour.

Turning is a machining process that uses a rotating cutting tool to remove material from the outside of a workpiece. This can be done by feeding the workpiece into the cutting tool or by holding the cutting tool against the workpiece.

The mill & turn process combines these two processes into one, allowing for the creation of parts and products with a high degree of accuracy and precision.

What are the benefits of using a CNC Mill & Turn?

There are many benefits to using a CNC Mill & Turn Service. Perhaps the most appealing benefit is the time and money it can save you. A CNC Mill can quickly and easily create parts that would otherwise be difficult or impossible to create by hand. This can save you a lot of time and money in the long run.

Another benefit is the level of precision that a CNC Mill can achieve. If you need parts that need to fit together perfectly, a CNC Mill is the way to go. The level of precision offered by a CNC Mill is simply not possible with other methods.

Parts made with CNC Millin

CNC milling is a popular manufacturing process that is used to create parts and components with a high level of precision. This process involves the use of computer-controlled milling machines to remove material from a workpiece to create the desired shape. Some common parts for CNC milling include:

-Fittings: Milled fittings can be used to connect two or more parts together.

-Enclosures and housings: Custom-milled enclosures can be used to protect internal components in electrical devices and other products.

-Brackets: Milled brackets can be stronger and more complex than sheet metal brackets, and can include custom threads and holes.

-Gears: CNC milling can be used to produce straight and spiral gears for mechanical devices.

-Mold tooling: Milled tooling made of steel or aluminum can be used for rapid prototyping of molded parts.

-Engine parts: Automotive engineers can use CNC milling to create engine blocks and other parts.

-Medical devices: CNC mills can be used to produce implants, surgical instruments, and other medical devices.

-Water pumps: Multi-axis mills can create reliable impellers for hydraulic equipment.

-Forming punches: CNC mills can also be used to create forming punches for sheet metal fabrication.

Parts made with CNC Turning

CNC turning is similar to manual turning, but CNC turning offers greater precision and repeatability. CNC turning can be used to create parts with complex geometries, and it is often used in the production of high-precision parts.

– Rollers: CNC lathes can fabricate rollers with tight tolerances for industrial use

– Ball joints: CNC turning is ideal for rounded connective devices like ball joints

-Nuts and bolts: The accuracy of turning makes it suitable for tolerance-critical items like nuts and bolts

-Shafts: Shafts with rounded profiles are highly suited to CNC turning

-Flanges: CNC turned flanges can strengthen beams and pipes

-Nozzles: Nozzles are typically cylindrical or conical with hollow insides, making them suitable for CNC turning

-Turbines: CNC turning can produce round turbine blades for the energy industry

– Firearms: A CNC lathe can produce the tubular shape required for a firearm barrel

FRIMA, the best CNC Mill & Turn Service Provider

If you are in the market for a CNC service provider, it is important to choose one that is experienced and has a good reputation. Look no further than FRIMA. We are a leading provider of CNC Mill & Turn Services, and we are dedicated to providing our clients with the best possible service. We offer a wide range of services. We are confident that we can meet your needs.

Our team of experienced professionals is ready to assist you in any way possible, and we are confident that we can provide you with the best possible service. Contact us today to learn more about our services, or visit our website to learn more about our company.